Many customers get confused when it comes to choosing the top materials for Tulip Table Base. There are at least five options in the market. On top of that, various suppliers and customers have their preferences.

I am Baggio. I’ve been with Marble Table for 20 years and 10 years with Mid-Century Modern Reproduction furniture since 2010. The knowledge I’ll share with you will point you in the right direction.

The top three materials for Tulip table bases are:

- Cast Aluminum: Cast aluminum is formed by pouring molten metal into molds that have been shaped by a pattern of the desired final product.

- Metal (Steel): Steel is an alloy made up of iron with a usually minute quantity of carbon to enhance its strength and fracture resistance.

- Fiberglass: This is a common type of fiber-reinforced plastic using glass fiber.

There are a lot more interesting details on these materials for Tulip table bases. I’m sure you’ll be looking forward to the next section, where I’ll discuss details such as price levels, strength, fixing way, and shape.

There are a lot more interesting details on these materials for Tulip table bases. I’m sure you’ll be looking forward to the next section, where I’ll discuss details such as price levels, strength, fixing way, and shape.

1. Price Levels

Cast Aluminum

This type of aluminum is usually one of the most expensive in comparison to other kinds of aluminum. The authentic Saarinen Table Base is manufactured with cast aluminum and has a glossy or matte lacquer finish. It is used for high-quality reproduction.

There are three popular types of molding techniques for producing castings:

The table below shows the comparison of prices between cast aluminum and other variations.

| Metal | Price per pound |

| Cast Aluminium | 20-30 cents per pound |

| Dirty extruded aluminum | 10-15 cents per pound |

| Aluminum sheet | 15-20 cents per pound |

Although aluminum is more abundant than iron underneath the earth, it is more expensive than iron. You might find this odd since we all know that scarcity creates value. But, the reason for the difference in value between these alloys is the vast amounts of electricity required to extract the aluminum ore.

Metal

Steel is moderately priced. It’s good for middle-high quality reproduction tables. The table below shows the most recent price of steel per ton. It is about 40-50% cheaper.

| Metal | Price per ton | Date published/updated |

| Steel | $230 per ton | 30th June 2021 |

In February 2021, there a small dip in prices. You might find this odd since we all know that scarcity creates value. But, domestic steel prices gained traction the following month.

Fiberglass

The price of fiberglass is between $4.5 and $5 per square meter. The precise price depends on the supplier you’re buying from. But you can easily plan your budget with the above-given range depending on the quantity you want to purchase. It is about 20-40% cheaper. It’s good for middle-high quality reproduction.

2. Strength

Cast Aluminium

Your guess as to the strength of this metal alloy is as good as mine; it’s incredibly strong. Directly below, you’ll see the strength of the cast aluminum carefully detailed in a tabular format:

| Properties | Metric | Imperial |

| Tensile Yield strength (0.2%) | 152 MPa | 22000 psi |

| Ultimate Tensile strength | 221 MPa | 32000 psi |

| Shear strength | 180 MPa | 26100 psi |

| Fatigue strength (R.R. Moore test, @#of cycles 5.00e+8) | 60 MPa | 8700 psi |

| Shear modulus (estimated from Aluminum 770 / Aluminium) | 26.5 GPa | 3840 ksi |

| Modulus of elasticity | 70-80 GPa | 10153-11603 ksi |

| Elongation at break (AA; in 2 in.) | 3% | ≥ 3% |

| Poissons ratio | 0.33 | 0.33 |

| Charpy impact, unnotched | 16.3 J | 12.0 ft-lb |

| Charpy impact (v-notch) | 3.40 J | 2.51 ft-lb |

| Hardness, Knoop (estimated from Brinell Hardness) | 98 | 98 |

| Hardness, Brinell (AA; typical; 500 g load; 10 mm ball) | 60 – 90 | 60 – 90 |

| Machinability (0-100 Scale, where 100 is best) | 90 | 90 |

| Hardness, Vickers (estimated from Brinell Hardness) | 85 | 85 |

The following units denote:

- Psi – Pound per square inch

- Ksi – Kilopound per square inch

- MPa – Megapascal

- GPa – Gigapascal

- J – Joule

Cast aluminum has some interesting qualities such as:

- Being lightweight

- Having highly dimensional stability to very complex shapes and thin walls

- Strong resistance to corrosion

The cast aluminum has similar physical and mechanical properties with other aluminum components. On completion of the casting process, cast aluminum swiftly creates an outer layer of aluminum oxide that is corrosion-proof.

We use heat to treat our cast aluminum to improve its toughness or tensile properties for specific applications. First, we heat the metal to a specific temperature. This allows the basic microstructure to evenly distribute across the total length and width of the material. Then, we rapidly cool the metal, which will trigger the evenly distributed pattern of the microstructure to stay put and give us the ideal properties we seek in our cast aluminum.

We don’t treat with heat. We finish them using cold working by primarily rolling them. This enhances the tensile properties of the metal because compacting the molecules together decrease flaws in microstructure.

Metal (Steel)

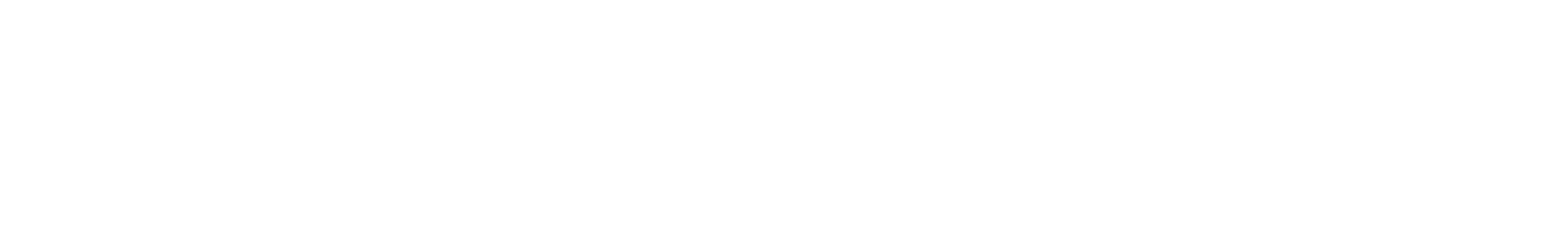

There are various kinds of steel. The normal model is thin-shelled (1.5-1.7mm) and delicate with shaky support.

Then, we have a very solid model. It has a thick shell (2mm) and an extra central support system. It’s completely safe as a base for our Tulip tables.

Below is the display of the mechanical/tensile properties of steel in a tabular format:

| Tensile properties | Metrics | English | Commentaries |

| Hardness, Brinell | 121 | 121 | Differs broadly with composition and heat treatment |

| Hardness, Knoop | 140 | 140 | Differs broadly with composition and heat treatment |

| Hardness, Vickers | 126 | 126 | Differs broadly with composition and heat treatment |

| Ultimate tensile strength | 420MPa | 609000psi | This denotes the value for AISI 1020, mild steel. Values can vary from 295 – 2400 MPa, owing to factors such as composition and heat treatment |

| Yield tensile strength | 350MPa | 50800psi | AISI 1020 Steel. Yield strength differs similarly to Ultimate Tensile Strength values, from 200 – 2100 |

| Elongation at break | 15% | 15% | AISI 1020. Typically, elongation lessens as hardness and tensile strength increases |

| Modulus of elasticity | 200GPa | 29000ksi | Nil |

| Bulk modulus | 140GPa | 20300ksi | Nil |

| Poissons ratio | 0.25 | 0.25 | Measured |

| Machinability | 65% | 65% | These values are for 1020 steel. The values differ from 0 – 100. Based on 100% machinability for AISI 1212 steel is 100%. |

| Shear Modulus | 80GPa | 11600ksi | Nil |

Fiberglass

The fiberglass is very strong, You can also get More of Fiberglass Properties here.

but you should ensure you’re buying one manufactured with high-quality resins and glues. Fiberglass made with glues and resins of low quality may experience flaking and cracking after a short while.

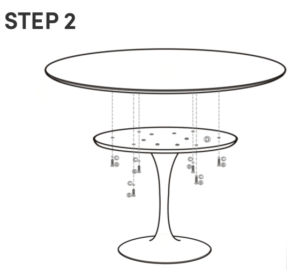

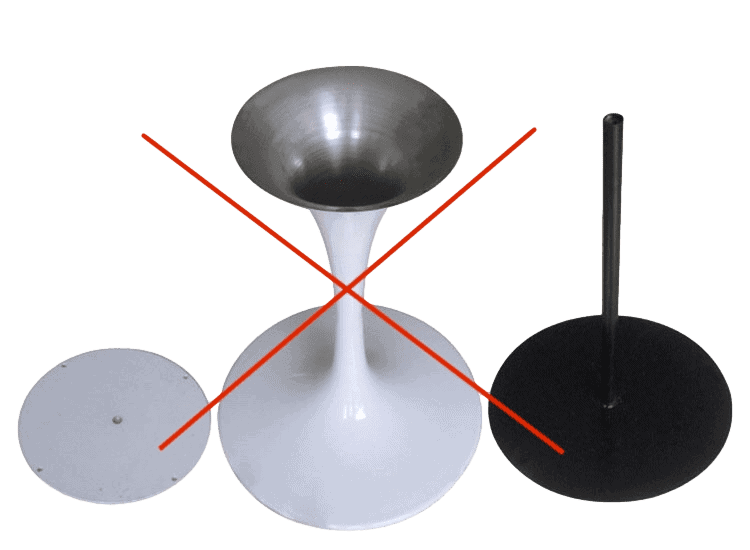

3. Fixing Way

Cast Aluminium

Metal

Fiberglass

4. Shape

Cast Aluminium-Round +Oval

Cast aluminum Tulip table (round shape)

Cast aluminum Tulip table (oval shape)

Metal (Steel)-Only Round

Steel Tulip table (round shape)

Fiberglass-Round + Oval

Fiberglass Tulip table (oval shape)

Conclusion

In terms of the highest quality level, Cast aluminum is the best, strongest but the least budget-friendly compared to the other two. Metal (steel) is also a good choice if you’re aiming for a Tulip table of middle-high quality. It’s more budget-friendly and considerably strong. Yet, I recommend the thick-shelled base with very sturdy support. Fiberglass is another good choice for you, considering the factors such as its strength and price. I recommend you purchase from reputable partners to get the best value for your money.

Massimilano is China Wholesale supplier for Tulip Table Base, and offers a vast range of tulip tables in Italian quality, serving more than 100 brands since 2010. You can also check our products and send your inquiry.